OSMS has studied how maker communities of different countries individually responded to the crisis. We explored how they solved problems specific to their geography, society and other factors. We provide the resulting insights in the form of individual national case studies for free, vetted for accuracy by the respective national maker communities. These case studies serve as a blueprint for maker groups in countries that want to establish or improve nation-scale coordination.

History

Image: OSMS

The movement started from a network of people who were slowly pulled together into a large Telegram channel in March 2020. Members of this group included people from various industries including government officials, doctors, engineers, and health officials.

The original group attempted to design an open-source ventilator. This soon transformed into a Telegram channel created by Ester Boaro, director of the Technological Institute of Aragone (ITA) after a Twitter conversation with other people. Said Telegram channel served as an information chain to collaborate on understanding how to build PPE quickly and efficiently. There was little structure or bureaucracy.

Miguel Angel Casanova approached the group with the www.CoronaVirusMakers.org website he had put together. Separately, a forum was made by Cesar Garcia and David Cuartielles, where people could post information regarding 3d models and blueprints for PPE creation, and general information about the status of the movement. Soon, the forum merged with the website as a way to offer a unified response.

In parallel, a Whatsapp group created by Jorge Barrero, director of COTEC (the Spanish foundation for innovation) where topics mainly around ventilator design were covered by a group of innovators working in parallel on different designs.

Eventually, Karim Asry, co-founder of Espacio Open and Co-producer of Maker Faire Bilbao was one of the initial 27 group members in said Whatsapp group working on Ventilators and joined forces with David Cuartielles, co-founder of Arduino and professor at Malmo University to coagulate the website, forum, Telegram group and WhatsApp group into one cohesive movement.

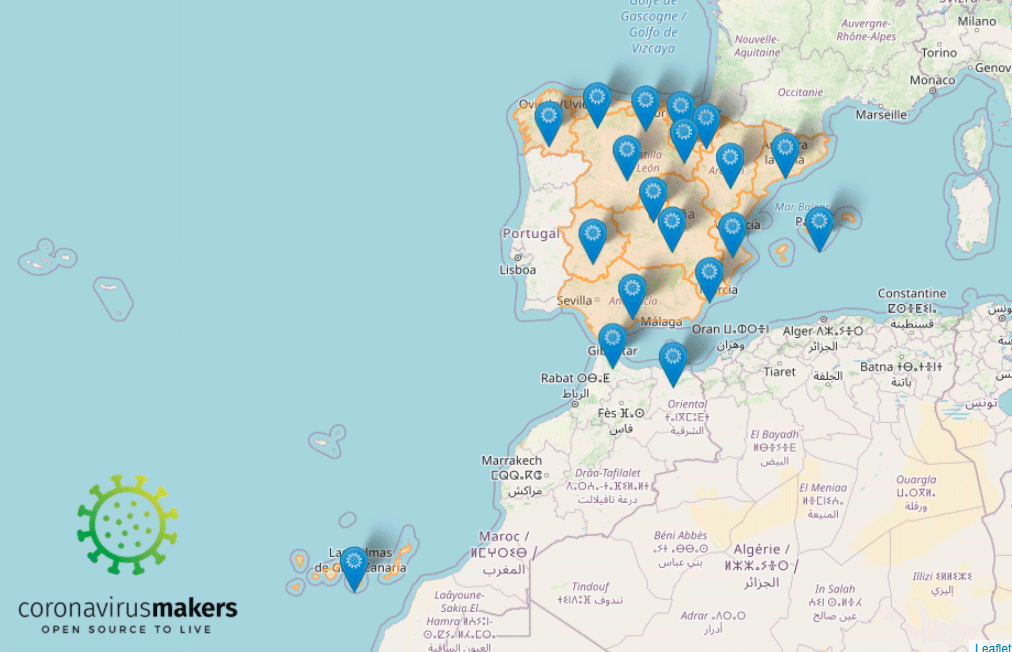

Source: coronavirusmakers

As the group grew they began to form connections with healthcare centers in all 17 regions of Spain. This allowed the group to understand where supplies were needed (demand awareness) as well as provided them contacts in the police and military that were able to form supply chains from makers to hospitals where PPE was needed.When the Spanish police came looking for face masks, makers shared their designs and material providers. The police started their own factory based on the police designs and materials. Karim Asry’s makerspace was hosted in a small cookie factory and repurposed it to create PPE. They would extend their blueprints and supply chains out to other makerspaces to help speed up and increase production. This lead to other ad-hoc makerspaces being created.

There wasn’t so much nationalization as organization with CoronavirusMakers simply aiding in communication between the various makerspaces. Each makerspace still continued to operate on their own in terms of organization. Coming together seemed to grow naturally with one step leading to another. Coronavirusmakers is one of the largest organizations of its kind world-wide, with 20,000 volunteers involved in its operations at its peak in May 2020.

Additional organizations have also sprung up with the sole purpose of connecting people, such as CovidWarriors and Frena La Curva.

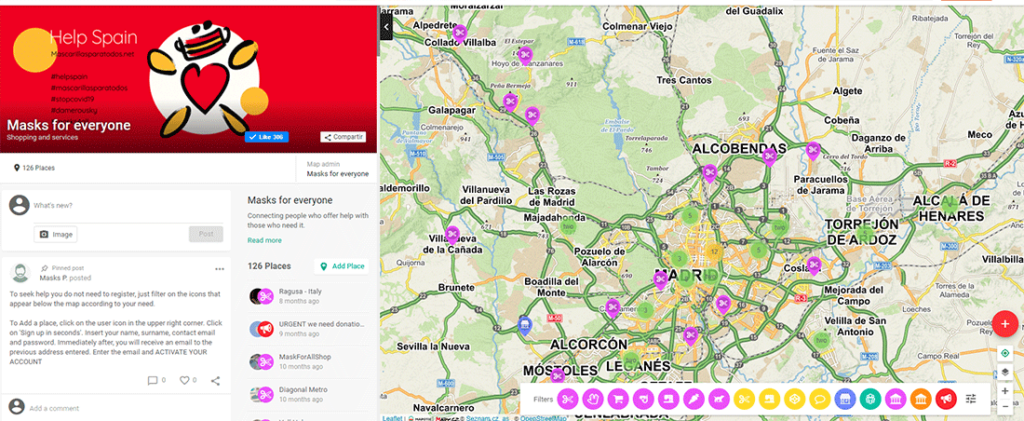

Mascarillas Para Todos is a Spanish movement inspired by the Czech movement #Masks4All .This movement was born in the Czech Republic where wearing face masks had been mandatory from the beginning. This movement inspired the creation of maps across the Czech Republic, Germany and Italy. Martin Hassman and Raquel Quevedo worked with the Czech teams to stand up the Mascarillas map wrapped in a nonprofit and non-governmental website created by volunteers that serves as a marketplace for Coronavirus emergency needs – such as services or PPE production/distribution.

Source: Mascarillasparatodos

Mascarillas Para Todos differs from Coronavirus Makers in that it takes no active role in the organizing process, but serves strictly as a matchmaking and communication tool offering the ability for people to put their location and offering services on a map. This map connects people in need of help with people who offer help and equipment. People can post various services such as offering or needing masks or visors, 3d printing, and even offers to walk dogs or run errands for essential workers. Each post comes with a short description and contact info to be able to get in touch with that individual. They also organized weekly national workshops all over Spain to discuss materials, distribution methods and challenges, and got assistance in sewing from the Czech Republic through Bohdana Goliasova and Martin Hassman. Fabric was sent to Africa, and Mascarillas collaborated with makers in South America to pass on insights.

2. Management /Reporting Structure

Management in general is fairly decentralized without a specific hierarchical structure.They have regional representatives in each of Spain’s 17 regions that handle organization with the healthcare centers there. The function of the national structure is to provide information to small makerspaces and healthcare providers.

The emergent organisational structure was built to include the following:

- A national committee with representatives from all of the different regions in Spain (17 communities + 2 autonomous cities),

- an overall R&D coordination team,

- a communication group,

- an economic committee handling donations and how those would be distributed to sub-projects applying for funding.

The national organization facilitates communication between health care services and makers to organize what type of supplies are needed. They partner with the police and military to facilitate supply routes. The group itself consists of 20,000+ members and 74+ companies are involved in total.

- Many organizations are 3d printing companies or injection molding companies that have aided in 3d printing more masks.

- Some organizations are tech companies and universities that are aiding in creating new designs for PPE and Ventilator models.

- Other companies are donors and creating contributions to the group to go towards supplies and organization

Supplies go straight to healthcare providers, with supply chains being aided by police and military organizations. Communication for the general public is done through their website where they have a forum and posts about new information and building techniques. Group members communicate through Telegram.

An additional aspect of their work is to try to link supply chains together, working with organizations and members of local and national governments to facilitate the delivery of PPE equipment

Data Management

Data is collected and updated every 10 days at Coronavirusmakers, and tracked across each of the 17 regions, each of which produces different kinds of supply.

The data is managed by one person, who accumulates the regional data into a national spreadsheet, with different tabs for each week. Besides this national register of information, there were regional teams that accounted for the donations within their community. Since the national structure was not fast enough in producing a national interactive supply<>demand tool, some regions went on and created their own tools to visualise their efforts.

The central organization manages a simplified map based on OpenStreetMap that shows the cumulative amount and kinds of PPE created in each region (as opposed to specific cities), totaling more than 1 million pieces of PPE produced within the Coronavirusmakers organization.

Mascarillasparatodos has an interactive map interface as its primary website interaction tool, which breaks 120 maker and supplier listings down to GPS coordinates across Spain, and provides the ability to contact specific organizations directly.

Source: mascarillasparatodos.

Politics & Enablers

The group is well connected with local governments throughout Spain. State run healthcare centers and the group organizes with local police as well as military officials mostly to secure supply routes as well as provide some transportation for doctors and other healthcare officials.

Funding

Funding was orchestrated via the Ashoka Foundation who offered the pro bono support of an accountant, as well as a bank account dedicated to the movement. The budget was decided on a rolling basis by a committee where Makers, industry organizations, the National Foundation for Innovation and the fourth sector were represented. Anyone in the organisation could request money for any kind of action. As soon as the request was made, the committee would meet – up to 5 days per week – to resolve whether the project should get funding or not. Most proposals were approved.

The group initially began to receive financial donations from individuals and corporations which were mostly used to facilitate transportation for doctors and healthcare workers as needed. Additional funds, once the project had set up its initial infrastructure, were used to kickstart more industrial processes and create more high priced items, such as the steel molds for injection molding (with costs of $5,000-$10,000 per set of molds).

Close to 1.5 million supplies were produced, as summarized in this video by Coronavirusmakers:

Future

Since June 2020, much of the emergency efforts of Coronavirusmakers and other groups were ramped down (since demand had been met), and energies and communities transformed into RED Internacional Maker, a new organization focused on international cooperation and Open Source health efforts. The group was co-created by Roberto Garcia-Patron and focuses on “Manufacturing 4.0”, projects spanning multiple countries in Latin America, Spain, Ireland and France, and pursues long-term projects – rather than the initial emergency response taken up by its predecessor organizations.

Links / Press

- https://www.coronavirusmakers.org/

- https://www.mascarillasparatodos.net/

- Video Interview on Natl. Response by Plan C

- Mascarillas YouTube Channel

- https://helpspain.website/

- www.somosrim.org

Read Further Case Studies

Germany

Germany demonstrated resilience through a decentralized network of 180 regional maker hubs that coordinated among 7,000+ makers to produce hundreds of thousands of PPE supplies during the COVID-19 outbreak.