OSMS has studied how maker communities of different countries individually responded to the crisis. We explored how they solved problems specific to their geography, society and other factors. We provide the resulting insights in the form of individual national case studies for free, vetted for accuracy by the respective national maker communities. These case studies serve as a blueprint for maker groups in countries that want to establish or improve nation-scale coordination.

History

Germany has a population of 83 million people. Like other countries, Germany’s existing and well-connected Maker movement ramped up its response to COVID within small localities and Facebook groups, and was eventually able to loosely organize the response in a national organization.

On the heels of the nationwide 48-hour hackathon #WirVSVirus on March 20 (started by independent organizations, eventually supported by the national German government, in the end involving 28,000 participants within Germany), many relationships were made and awareness-driven momentum was created. This helped kickstart the national maker effort that was already slowly underway since COVID first reached Germany in late January 2020. Also, the hackathon involved a lot of loud evangelists and the German startup scene.

Image: Maker VS. Virus, Germany

Maker vs. Virus, Germany’s largest group, was initially conceived and created by Kassel Makerspace Hammertime and Melania-Simona Moise on March 24, 2020 directly after a pilot run during #WirVSVirus. It came with a slack channel and a mission.

Parallel to this, a number of ad-hoc Facebook groups discussing COVID reponses sprung up as the outbreak of the virus grew. These groups allowed makers and leaders to share ideas with each other, including Andreas Kopp, founder of Erfindergarden in Munich, and Nils Hitze, community organizer and founder of the first German Maker Faire. Andreas was a part of Germany’s FabLab network as well as Germany’s existing national maker coalition, Verbund Offener Werkstaetten, (connecting nearly 400 Makerspaces across Germany) which allowed him and his network to quickly coordinate amongst each other in the move to shift to creating PPE.

As independent maker spaces like Erfindergarden ramped up production, they realized the real problem was distribution. In some regions, the sourcing of clear PETG sheets for face shield visors was also a big problem.

Similar to Spain, the national movement came somewhat organically as various larger makerspaces networks around the country began to loosely organize in order to create the most efficient production pipelines. At that point, Germany was already able to look at other countries’s responses, like Spain’s Coronavirusmakers.org. With lower infection numbers and less pressure, the Germans were able to build their movement partially inspired by how other countries went about it.

Organizations across Germany began to collaborate, which helped in connecting with industries that could offer materials as well as assist in distribution where it was most needed. The initial founding team concentrated on making, and the organization needed an organizer with lots of available time and communication abilities. Nils Hitze took on the leadership role at Maker Vs. Virus organically after posting thousands of organizing messages in the Slack channel, and began reaching out to other Makerspaces and larger Facebook groups to invite them to join the Maker VS Virus, so everyone could join a unified group. For the German-speaking Austria and parts of Switzerland, they also organized as regional hub-structures under the Maker vs. Virus roof.

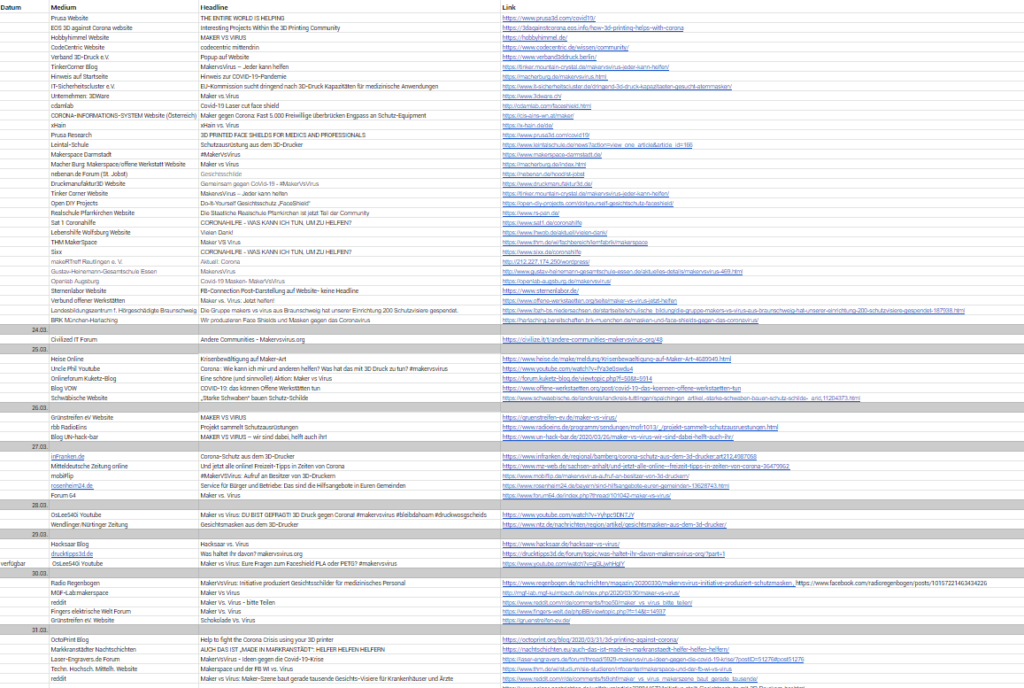

Image: Maker VS. Virus, Germany

In the early stages of the organization the Maker VS. Virus team tried to create a centralized national organization to help link makers together, but quickly found that it was too cumbersome as a model and realized the need to use a decentralized model, similar to Coronavirusmakers in Spain.

An essential component to get different maker organizations to come together in one organization was to invite the individual leaders into the main Maker VS Virus Slack channel, and getting them to list on the big map. This created an internal community, and leaders were willing to join their efforts with Maker VS Virus. People began delivering materials and supplies to the Makerspace in Munich as well as facilitated volunteer transportation of finished masks.

One other essential component was that the Maker VS Virus team would tag people and keep throwing them at the initial Slack channel. The team also brought on Alexander Klarmann, a PR specialist with a history in the maker movement. Together with Nils Hitze he had founded Germany’s first Maker festival in Munich and the two crossed paths rather coincidentally again as leading characters in the Maker vs. Virus organisational core team. Klarmann reached out to tons of journalists, created a proper press package including a press page and a Google Drive press kit. This focused PR effort gave Maker VS Virus the biggest PR footprint the German maker scene has ever had, both nationally and internationally, which created wide awareness within the country and funneled most medical requests to Maker VS Virus rather than the other German groups. The count of online and print articles, radio and TV reports exceeds 340 individual reports in under 3 months.

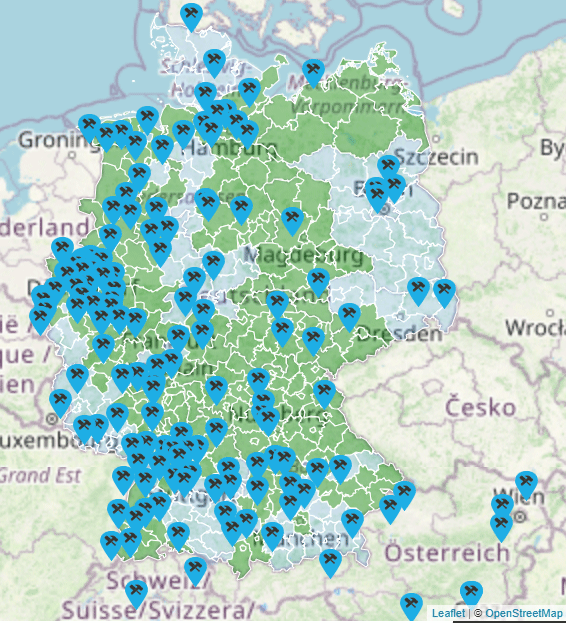

Image: OSMS

They created a system in which larger makerspaces would host a regional coordination hub in their area and begin handling the local organization and logistics of creating necessary supplies. As of June 2020, there are 154 Maker-hubs listed on Maker VS. Virus’ website.

Most of the production and organization is done regionally rather than nationally. Although Maker vs Virus is technically a national organization, it merely helps organize and connect the various pre-existing local maker structures that exist throughout Germany. But the Germans introduced the regional clustering “Maker Hub” model.

A significant improvement of the Hub model to the prior ecosystem is that it mobilized and empowered makers and private 3D printer owners outside of the classic Makerspace / FabLab ecosystem, many of who hadn’t been part of “the community” prior. It was a true crowd-sourcing efforts, where private individuals clustered around their regional hubs which hosted the organizing efforts. Many of these private makers were motivated to join or start their own Makerspaces and alliances beyond the COVID-19 response due to the experience they had.

Parallel to Maker VS Virus, other smaller organizations stayed relatively independent. One of them was Vechta Gegen Corona, created by Dominik Wilming. They initially built face shields with 3D printers, but were eventually able to utilize industry contacts and shifted their production to injection molding, yielding 3,500+ visors a day.

Maker vs Virus was able to help them in improving distribution and connecting them with the people who most required the face shields. Vechta Gegen Corona consists of 10 companies/organizations and dozens of private makers that banded together regionally.

Parallel to the face shield efforts, there were also a lot of mask sewing groups in Germany. They were already really well-organized and connected before COVID hit, so they worked independently.

Management & Reporting Structure

Maker vs. Virus serves a loose framework for various sub-networks throughout Germany. Through the website makers can be paired with regional hubs that then help organize and fit individual makers into the supply chain for that specific region.

Each regional hub, 180 throughout Germany, self organizes and shifts based on the specific region’s needs. The coalition is composed of individual makers, fablab networks, and about 10 different companies that have contributed to creating injection molding to speed up production.

MakerVS Virus had the most visibility out of the groups that sprung up, and had individuals who only focused on organizing rather than making (such as Nils Hitze, who took over leadership of the group), which allowed for further infrastructure-building within the ad-hoc organization, which gave the grounds for a management and reporting structure, and incentivized other groups to join them.

Many of the larger hubs that have sprung up have shifted almost entirely to injection molding in order to free up 3d printers for other R&D into PPE gear.

Image: Maker VS. Virus, Germany

Most of distribution is done through volunteer networks paired with organizations such as the German Red Cross that have aided in moving supplies to the necessary hubs and locations.

Maker vs. Virus helps organize the hubs so that they can be contacted and loosely organize any national efforts necessary between the hubs. Each hub has a specific point of contact that is responsible for the makers in the region and helping the organizing efforts.

The function of the national structure is to optimize production and supply lines so that makers can be directly in touch with individuals and companies and materials as well as the healthcare facilities that most require the visors.

There were multiple projects that tried to do a supply<>demand matching engine, but development was too slow so the team transitioned to using Trello and Google Sheets to track job requests and deliveries done.

Each Hub had one hub organizer, and one deputy; that group of people had a Slack channel that was private among leadership. Some people needed training since they never organized before, and it required moderation since many people came in with lots of energy but not necessarily organizing experience, and making everyone get along was a challenge. As time went on, many of the first-time organizers grew personally, so the organization became smoother as time went on.

Communication is conducted primarily through Slack; outreach was mostly done through Facebook. As the movement matured, outreach shifted towards articles and journalistic media coverage as a driver of awareness, as well as Ebay Classifieds and other classifieds listings.

Maker VS. Virus Slack Statistics

Slack Channel Members

Slack Channels

Hub-specific channels for local coordination

Data Management

Image: Maker VS. Virus, Germany

Maker vs. Virus keeps track of the various hubs throughout Germany, and keeps a loose data reporting structure through a spreadsheet on how much PPE is being created from their various hubs; reporting isn’t enforced much though, so the data is somewhat incomplete, and only tracks within the network.

This spreadsheet was built primarily to get a picture of daily production capability at the peak of the crisis, but didn’t last very long since it took a lot of manual work to keep collecting information from makers – so it served more as a momentary snapshot rather than a long-scale tracking effort.

There is a map that highlights the various hubs throughout Germany, however they do not provide the amount of PPE created within each hub. Other, smaller organizations such as Vechta Gegen Corona do keep rough track of data regarding the cumulative amount of equipment being produced within their organization.

Politics & Enablers

For the most part the national government has been relatively unresponsive in terms of aiding the maker movement. One of the makers, Anke Domscheit-Berg, a member of parliament, has noted that the national and even local governments have been relatively unresponsive in terms of their assistance in funds and supplies. In some municipalities and governments though, local authorities have provided financial support or help with organisation and distribution of the PPE.

Public transit authorities and other local infrastructure organizations reached out with requests, and collaboration with makers was common. The Maker VS Virus organization also coordinated with German injection molding companies to help them choose the right designs.

Funding

For support, the movement has found a lot of allies in industry that have put up a large amount of money in order to participate in creating PPE. In many cases the typical German “Mittelstand” (Medium Sized Companies) have been relatively quick to support with production like visor foil and injection-molded headpieces. Additionally, the movement has received funding from organizations like the German Red Cross which helped establish supply lines.

Most of the money that is received by the national organization Maker vs Virus is through private donations from individuals and companies. Donations to Maker vs. Virus were all routed through the non-profit Verbund Offener Werkstaetten which go towards the various workshops creating PPE within the network to purchase supplies and aiding transportation. The Verbund provided a non-profit fiscal sponsorship structure to Maker VS Virus, which allowed immediate donation abilities; founding their own NGO would have delayed the organization too much.

Links / Press

Read Further Case Studies

Brazil

Despite enormous infrastructure challenges, Brazilian makers have stood up a decentralized national response resulting in 1 Million + pieces of PPE made across hundreds of maker groups, with a growing nation-wide coalition.